.png)

Understanding Wire to Board Connectors: A Comprehensive Guide for OEMs

What Are Wire to Board Connectors?

Wire to Board connectors are electronic components that connect wires securely to a printed circuit board (PCB). They typically consist of male and female components such as headers, terminals, and housings. Their primary functions include establishing stable electrical connectivity and providing mechanical support.

Why Use Wire to Board Connectors?

Simplified Assembly and Maintenance

WTB connectors allow quick and straightforward assembly, significantly reducing production time. Their modular nature also simplifies maintenance, allowing easy disconnection and reconnection.

Enhanced Reliability and Signal Integrity

By providing robust connections, WTB connectors maintain excellent signal integrity and reduce the risk of failures caused by vibration, shock, or environmental factors.

Flexible Design Options

Wire to Board connectors come in various shapes and sizes, offering flexibility to designers working with limited space constraints, which is crucial in compact electronic applications.

Cost-Effectiveness

Efficient mass production capabilities and ease of assembly contribute to lower overall production costs, benefiting OEM operations substantially.

With these advantages, Wire to Board connectors are essential components widely used in various applications such as:

- Consumer electronics: smartphones, wearables, home appliances

- Automotive electronics: infotainment systems, vehicle sensors

- Industrial machinery: robotics, automated equipment

- Medical devices: diagnostic equipment, patient monitors

- Telecommunications: data communication systems, networking equipment

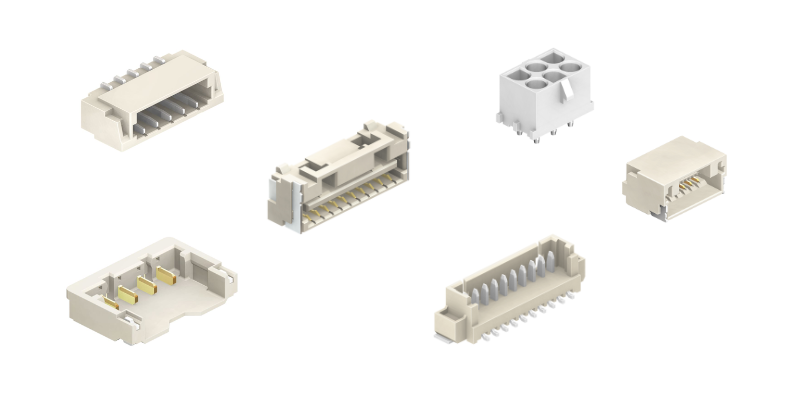

Types of Wire to Board Connectors

The type of Wire to Board connector defined depends on several factors, including how it connects to the wire, its mechanical and electrical characteristics, termination method, locking mechanism, and the application's specific requirements.

Wafer Connectors

Wafer connectors are compact electronic interconnect devices designed to establish reliable electrical connections between wires and PCB or between two PCBs.

Their slim, flat profile makes them especially suitable for compact devices like smartphones and tablets. Designed for efficient integration, wafer connectors can accommodate multiple connection points within a small footprint, allowing engineers to achieve high circuit density without sacrificing performance.

They ensure stable electrical connections through secure locking features that guard against vibration or mechanical disruption. With precision engineering, these connectors support optimal signal integrity and conductivity, which are critical for high-speed or low-power applications.

IDC (Insulation Displacement Connectors)

An insulation-displacement contact (IDC), also known as an insulation-piercing contact (IPC), is an electrical connector designed to attach directly to insulated wires without requiring the insulation to be stripped beforehand.

IDC connectors are compatible with solid and stranded wires and support a variety of wire gauges, making them versatile across different systems. They are often designed with strain relief features and robust contact springs to ensure resistance to vibration and thermal shock, which is essential in demanding environments. As a result, IDC connectors are commonly found in telecommunications equipment, network devices, industrial control systems, automotive assemblies, and consumer electronics. Their modular nature makes them easy to service or replace, helping reduce downtime and simplify maintenance.

.png)

Pin and Socket Connectors

Pin and socket connectors are a common type of electrical connector used to join circuits using a mating pair. The male component, known as the pin or plug, contains metal pins that insert into the female component, the socket or receptacle.

The socket is designed with holes or conductive contacts that securely receive the pins, forming a tight and stable electrical connection. This setup completes the circuit and ensures consistent signal or power transmission.

These connectors are engineered with a gendered design to prevent incorrect mating and promote reliable alignment. They come in various configurations, including different pin counts, sizes, and layouts, allowing them to be tailored to various current and voltage requirements.

Built for durability, high-quality pin and socket connectors can withstand repeated connection cycles and are often designed to resist vibration, moisture, and environmental stress.

Used extensively across industries, these connectors are found in everything from printed circuit board (PCB) assemblies and consumer electronics to automotive systems, industrial machinery, medical equipment, and aerospace applications.

Crimp Connectors

Crimp connectors are electrical components that attach wires to terminals or other wires without soldering. They work by inserting a stripped wire into the connector and then compressing (crimping) the connector onto the wire using a specialised crimping tool. This creates a tight, reliable electrical and mechanical connection.

Crimp connectors offer durability and reliability, especially useful when customisation is needed. Ideal for applications requiring robust connections.

More connector options for smarter PCB designs

Beyond the commonly mentioned connectors, many Wire to Board connector types are designed to meet different performance, size, and application requirements. These connectors serve specialised roles across industrial, consumer, and automotive electronics. While each has its own unique features and use cases, here are some additional Wire to Board connectors worth noting:

- Terminal Blocks

- Ejector Headers

- PCB Terminals

- Friction Lock/Locking Bar Connectors

- Power PCB Connectors

- Quick Disconnect Tabs

- Miniature and Micro Connectors

At Active Components, we help customers source reliable connector solutions that meet modern electronic design demands, whether for compact consumer devices, industrial automation, or high-performance applications. With a wide range of Wire to Board connectors and expert support, we make it easy to find the right fit for your project, ensuring performance, durability, and ease of assembly every step.

How to Source a Reliable Wire to Board Connector Supplier

Assess Supplier Reputation and Experience

Choose suppliers with a proven track record and deep industry expertise. Experienced suppliers not only offer reliable products but can also guide you in sourcing the right solutions for your specific needs, helping you avoid costly mistakes and ensuring long-term success.

Cost Efficiency and Long-term Value

A great supplier does more than deliver products—they help you find reliable solutions that save costs without compromising quality. At Active Components, we’ve helped numerous customers across New Zealand and Australia by providing trustworthy, cost-effective alternatives to major brands. When evaluating suppliers, consider competitive pricing and their ability to offer lasting value and a true partnership for your business growth.

Confirm Product Availability and Lead Times

Reliable suppliers maintain adequate inventory and predictable lead times to ensure your production runs smoothly. At Active Components, our warehouse facilities in both Hong Kong and New Zealand allow us to support Pacific-region customers with faster deliveries and flexible stocking solutions, helping you avoid costly delays and stay on schedule.

Evaluate Product Quality and Compliance

Select suppliers whose products meet international standards such as UL, RoHS, and ISO to ensure safety, reliability, and consistent quality. At Active Components, we partner with a global network of trusted suppliers with fully compliant connector solutions.

Ready to Find the Right Connector?

At Active Components, we help you simplify your sourcing journey with expert advice and reliable solutions tailored to your needs. Get in touch with our team today and discover how we can support your next project with the right connectors—on time, on budget, and built to last.