-(13).png)

Choosing the wrong connector is one of the most common causes of rework, field failures, and servicing issues in commercial and industrial electronics projects across Australia and New Zealand.

Connectors are often selected late in the design process, after key decisions around circuitry and power management have already been made. When selection is driven primarily by availability rather than suitability, it can introduce unnecessary risk in performance, installation, and long-term maintenance.

This guide outlines how to choose the right connector by evaluating electrical, mechanical, and environmental requirements, with a focus on the types of commercial and industrial electronics applications commonly designed and built across Australia and New Zealand.

Why Connector Selection Matters in Projects

In real electronics projects, connector selection is rarely just a technical detail. It has a direct impact on project timelines, installation quality, and long-term reliability.

Across Australia and New Zealand, many electronics projects operate under practical constraints that are easy to underestimate during design. Tight build schedules, limited on-site access, and reliance on local installers mean that a connector which looks acceptable on a datasheet can quickly become a source of delays, rework, or field failures.

Common real-world consequences of poor connector selection include:

- Project delays caused by long international lead times or a lack of local stock.

- Installation errors occur when connectors are difficult to terminate correctly using standard tools.

- Premature failures due to vibration, temperature variation, or environmental exposure.

- Increased servicing costs when connectors are hard to access, re-terminate, or replace.

In industrial and commercial environments, connectors are often exposed to conditions far less controlled than a lab or production line. Control panels may be installed in warm switch rooms, outdoor enclosures, or sites subject to vibration and dust. Equipment may also be serviced years after installation by technicians who were not involved in the original design.

In these scenarios, the “right” connector is not simply the smallest or lowest-cost option. It is the one that:

- Matches real electrical loads, not just nominal ratings.

- Can be installed efficiently using standard tools and common installation practices.

- Is available locally for both initial build and future replacement.

- Supports maintenance, inspection, and system expansion over time.

At Active Components, connector selection is guided by more than datasheets. With over 40 years of experience supporting electronics projects across Australia and New Zealand, the team works closely with engineers, panel builders, and system integrators to help select connector solutions that suit real installation conditions, long-term servicing, and requirements.

By working with established connector manufacturers and focusing on practical application requirements, we help customers reduce the risk of connector-related issues before they affect installation, commissioning, or ongoing operation.

For engineers, specifiers, and technical buyers, connector selection should therefore be treated as a risk-management decision, not just a component choice. Getting it right early helps reduce downstream costs, avoid rework, and ensure reliable system performance throughout the product lifecycle.

Step 1: Define Electrical Requirements (Beyond the Datasheet)

Electrical ratings are usually the first parameters engineers check when selecting a connector. In practical applications, however, simply matching datasheet values is often not enough.

Connectors are frequently used in environments where ambient temperatures are elevated, enclosures are crowded, and systems operate continuously for long periods. Under these conditions, connectors that are “rated correctly” on paper can still suffer from overheating, voltage drop, or accelerated contact degradation.

At this stage, the goal is not just electrical compliance, but long-term stability under operating conditions.

Voltage and Current: Design for Real Load, Not Just Nominal Values

Start by clearly defining:

- Continuous operating current.

- Peak or inrush current.

- Operating voltage, including transient spikes.

Many connector failures occur because selection is based on nominal load, without allowing for derating caused by temperature, enclosure airflow, duty cycle, or connector density.

Power, Signal, or Mixed Circuits

Clearly define the role each connector plays in the system.

- Is this connector carrying power, signal, or both?

- Are low-level signals routed near power conductors?

- Is noise immunity critical to system performance?

Power connectors prioritise current handling and mechanical strength, while signal connectors prioritise contact consistency and stable electrical characteristics. Using general-purpose connectors for mixed roles can introduce noise issues, intermittent faults, or long-term contact degradation.

In compact designs, this distinction becomes even more important as the spacing between conductors is reduced.

Safety Margins and Compliance Expectations

In AU/NZ projects, connectors are often part of systems that must meet electrical safety standards, inspection requirements, or customer-specific specifications.

Good practice includes:

- Selecting connectors with ratings comfortably above expected operating conditions.

- Avoiding designs that rely on perfect installation to remain safe.

- Choosing connector styles familiar to electricians and inspectors

These decisions reduce the risk of failed inspections, installation errors, and delays during commissioning.

Designing for the Entire Product Lifecycle

Electrical requirements should be assessed across the entire lifespan of the product, not just initial operation.

- Will loads increase due to future upgrades or system expansion?

- Will connectors be exposed to higher temperatures as enclosures age or layouts change?

- Will replacement parts need to be sourced many years after installation?

Choosing connectors with stable electrical performance and consistent supply support helps ensure that servicing, replacement, and expansion remain practical throughout the system’s life.

Step 2: Match Connector Type to Real Installation Scenarios

Once electrical requirements are defined, many projects encounter issues when connector selection is driven by form factor or PCB convenience, rather than how the system will actually be wired, installed, and serviced.

Electronics projects often involve multiple parties, design engineers, panel builders, electricians, and maintenance technicians. A connector that works perfectly in a CAD layout can become a source of installation errors, rework, or long-term reliability issues once it reaches the workshop or site.

Connector type selection should therefore be driven by installation reality, not design preference.

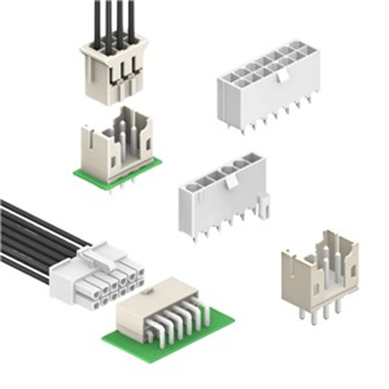

Wire-to-Board Connectors: External Wiring to PCBs

Wire-to-board connectors are used when external wiring needs to terminate directly onto a PCB.

Typical use cases

- Control boards inside commercial equipment.

- Building automation and HVAC controllers.

- Embedded systems with sensors, relays, or I/O modules.

Why they work in real installations

- Provide a clear termination point for electricians.

- Reduce wiring errors compared to direct soldering.

- Allow boards or cables to be replaced without rework.

Where problems occur

- Insufficient strain relief in enclosures with frequent servicing.

- Low-retention connectors are used where wiring is disturbed during maintenance.

- Compact connectors specified for environments with vibration.

In practice, wire-to-board connectors should be selected with mechanical robustness in mind, not just electrical rating or footprint.

Wire-to-Wire Connectors: Harnessing and Modular Wiring

Wire-to-wire connectors are preferred when wiring is assembled as looms or harnesses rather than terminated directly onto a PCB.

Typical use cases

- Pre-assembled cable harnesses.

- Modular equipment with removable sections.

- Systems requiring regular disconnection during servicing.

Why installers prefer them

- Faster on-site installation.

- Cleaner, more organised cable management.

- Reduced risk of incorrect termination.

Where problems occur

- General-purpose connectors are used in vibration-prone equipment.

- Inadequate locking mechanisms for frequently mated connections.

In many commercial and light-industrial systems, wire-to-wire connectors allow assembly work to be completed off-site, reducing installation time and improving build consistency.

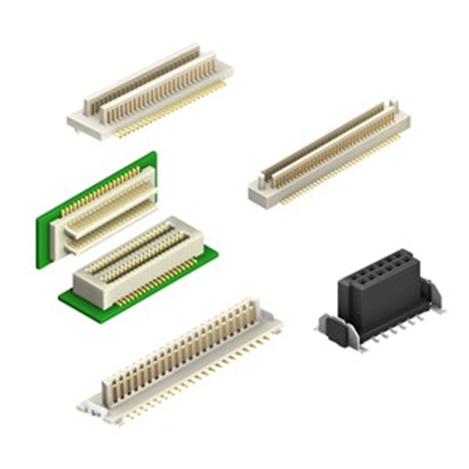

Board-to-Board and Pin Header Connectors: Internal Interconnections

Board-to-board connectors, including pin headers, are best suited for internal connections within an enclosure.

Typical use cases

- Expansion or daughter boards.

- Modular electronics assemblies.

- Internal signal routing between PCBs.

These connectors are not intended for field wiring. They perform best in controlled environments where vibration, moisture, and repeated handling are minimal. Using board-to-board connectors for external wiring often leads to installation difficulties, damaged pins, and intermittent faults, especially when accessed by technicians rather than assembly staff.

Terminal Blocks: Still the Industrial Standard

Despite the availability of compact connector options, terminal blocks remain a default choice in industrial and commercial installations across Australia and New Zealand.

Typical use cases

- Control panels and switchboards.

- Industrial automation systems.

- Machinery and plant equipment.

Why panel builders rely on them

- High current handling capability.

- Clear, organised wiring layout.

- Easy inspection, testing, and re-termination.

Terminal blocks align closely with standard electrician practices, making them a low-risk option for systems that require long-term support, modification, or compliance inspections.

At Active Components, connector selection is not limited to a single type or format. By working across a wide range of connector families, from terminal blocks and wire-to-wire systems to PCB and board-to-board solutions, the focus is on matching connector type to real installation conditions, servicing expectations, and long-term support requirements, rather than forcing a design into a predefined category.

Step 3: Consider Industrial vs Commercial Environments

Not all electronics projects operate under the same conditions, even when their electrical requirements appear similar on paper. One of the most common causes of connector-related failures is selecting components without fully accounting for the environment they will operate in.

In Australia and New Zealand, the distinction between “industrial” and “commercial” environments is often blurred. Equipment may be installed in locations that are technically commercial, yet experience heat, vibration, dust, or moisture levels closer to industrial use.

Misjudging this environment is a frequent source of premature failures and ongoing service issues.

Industrial Environments: Design for Harsh Reality

Industrial environments typically involve:

- Continuous or near-continuous operation.

- Elevated ambient temperatures inside enclosures.

- Vibration from machinery or plant equipment.

- Low tolerance for downtime or intermittent faults.

Common AU/NZ examples include manufacturing facilities, processing plants, infrastructure sites, and agricultural operations. In these environments, connectors are exposed to sustained mechanical and thermal stress. Electrical ratings alone are not sufficient — mechanical retention and long-term contact stability become critical.

Key connector considerations

- Secure mechanical retention, such as screw clamps or positive locking mechanisms.

- Robust housing materials that tolerate heat and vibration.

- Stable contact pressure over long operating periods.

- Clear, serviceable termination points for maintenance.

In practice, connectors used in industrial settings should be selected conservatively, even when the electrical load itself appears modest.

Commercial and Building Services Environments: Longevity and Serviceability

Commercial environments often include:

- Building services and automation systems.

- Equipment is installed in plant rooms, ceiling spaces, or service risers.

- Systems are expected to operate reliably for many years with minimal intervention.

While electrical loads are typically lower than in heavy industry, these systems are often serviced long after the original installation. Maintenance is frequently carried out by technicians or electricians who were not involved in the original design. In these situations, connector clarity, accessibility, and familiarity are as important as electrical performance.

Key connector considerations

- Easy identification and termination.

- Compatibility with standard tools.

- Clear separation of power and signal wiring.

Connectors that are difficult to access, unfamiliar, or fragile increase servicing time and the risk of wiring errors during maintenance.

Borderline Environments: Where Most Problems Occur

Many projects fall between industrial and commercial classifications. Common examples include:

- Light industrial workshops.

- Agricultural control systems.

- Outdoor commercial installations.

- Mobile or transport-related equipment.

These environments often expose connectors to vibration, temperature variation, moisture, or dust. This is where many connector failures originate: components are selected for commercial conditions but are unknowingly deployed in industrial-like environments.

In these cases, it is almost always safer to specify connectors with industrial-grade characteristics, even if the application does not appear demanding on paper.

Step 4: Field Servicing and Installation Realities

Connector selection does not end at installation. In many projects, the majority of a system’s lifetime cost comes from servicing, maintenance, and upgrades, not the initial build. A connector that is technically correct but difficult to work with in the field often becomes a long-term liability, driving downtime and rework.

Who Installs and Services the Connector?

In practical applications, connectors are often installed and serviced by electricians, panel builders, system integrators, and maintenance technicians. These users prioritise clarity, speed, and reliability.

Connectors that require specialised tools, complex termination methods, or unclear wiring layouts significantly increase the risk of errors during installation and servicing.

Well-chosen connectors support:

- Clear conductor entry and exit.

- Secure termination without excessive force.

- Visual inspection of connections.

Installation Efficiency and Error Reduction

On-site installation time has a direct impact on project cost and scheduling. Connectors that align with standard practices used by electricians and panel builders:

- Reduce installation time.

- Lower the likelihood of incorrect wiring.

- Simplify commissioning and functional testing.

By contrast, compact or unfamiliar connectors may save PCB space but often cost far more in labour, troubleshooting, and rework once the system reaches the site.

Servicing, Fault Finding, and Replacement

Most systems will be serviced multiple times over their operating life. When connectors are clearly labelled, easy to access, and simple to disconnect and reconnect, technicians can diagnose and resolve faults quickly and safely.

By contrast, connectors that require disassembly of unrelated components, awkward access, or re-soldering of wires increase downtime and often lead to temporary fixes or unsafe workarounds under time pressure.

Planning for Expansion and Modification

Many systems in AU/NZ are expanded or modified after initial installation. Common scenarios include:

- Adding new sensors or I/O.

- Upgrading control hardware.

- Modifying wiring due to site changes.

Connectors that support re-termination, modular wiring, and spare capacity reduce the need for panel rework and minimise disruption during future changes.

Step 5: Local Stock Availability and Lead Times (AU/NZ Focus)

In Australia and New Zealand, connector selection is not only a technical decision, but also a supply-chain and risk-management decision.

Many projects operate under tight timelines, limited buffer stock, and fixed commissioning deadlines. A connector that meets every technical requirement but cannot be sourced reliably and locally can delay builds, disrupt installation schedules, and significantly increase overall project cost.

Supply Continuity and Lead-Time Considerations

Across Australia and New Zealand, electronics projects often involve short production runs, phased installations, and long service lives with ongoing maintenance and expansion. In these scenarios, long or uncertain international lead times introduce real risk.

Local stock availability helps to:

- Keep builds and installations on schedule.

- Reduce exposure to freight delays and customs disruptions.

- Support urgent replacements during breakdowns.

- Avoid last-minute design changes caused by supply constraints.

For engineers and specifiers, selecting connectors that are supported and stocked locally is a practical way to reduce downstream project risk.

Lead Times, Redesign Risk, and Long-Term Support

One of the most costly connector selection mistakes is designing around a part that is available during prototyping but difficult to source later. This frequently leads to:

- Forced substitutions late in the project.

- PCB redesigns due to footprint or pinout differences.

- Requalification or re-testing.

- Inconsistent parts across production batches.

- Delays during servicing years after installation.

Designing with connector families that offer stable local supply, and long-term support helps protect projects from these risks.

Supporting Maintenance and Field Service

Many industrial and commercial systems across Australia and New Zealand remain in service for many years. When connectors are damaged or need replacement:

- Locally stocked parts allow rapid restoration.

- Maintenance teams can resolve faults without extended downtime.

- Projects are not dependent on overseas shipping for critical spares.

This is particularly important in control panels, building services, and infrastructure-related installations, where access is difficult and downtime is costly.

Local Availability as a Selection Advantage

Distributors with strong local stock holding and long-term supplier relationships can play a critical role in reducing lead-time uncertainty and supporting continuity across a product’s lifecycle.

For engineers, panel builders, and technical buyers, this means connector selections that are not only technically sound, but also practical to source, replace, and support locally over time.

Explore Connector Solutions with Local Support

Choosing the right connector is about more than meeting specifications. It’s about selecting components that work reliably in real installations, can be sourced locally, and remain practical to service throughout the system’s life.

Active Components supports electronics projects across New Zealand and Australia with a broad range of connector solutions, including but not limited to:

- Terminal blocks for industrial and commercial control systems.

- Wire-to-board connectors for PCB-based equipment.

- Wire-to-wire connectors for harnessing and modular wiring.

- DIN rail mounting solutions for control panels and switchboards.

- Pin header series for board-to-board and internal connections.

With a focus on local availability, supply continuity, and application support, Active Components helps engineers, panel builders, and technical buyers reduce risk from design and installation through to long-term maintenance.

👉 Explore our featured connector range:https://www.activecomponents.com/category/our-products/conn

If you’re developing a new design or reviewing an existing system, talk to us about selecting technically appropriate, locally supported connectors that help protect project timelines, reduce servicing effort, and improve long-term reliability.